13

Diagnostic Manual

ON BOARD DIAGNOSIS (OBD)

3

Position Description

3

0= Overall System

1= Secondary air system / mixture

preparation

2= Fuel System

3= Ignition System/Misfires

4=Additional exhaust gas

monitoring

5=Cruise control/Idle speed control

6= Input/Output signals, Control

Units

7= Gear Box/Transmission

8= Transmission

9=Transmission

A= Hybrid propulsion

B=Reserved

4&5 Serial numbering of individual

components or systems

Data Link Connector (DLC)

OBD II regulations require that manufacturers use

a standardized diagnostic connector. This is to

allow a generic scan tool to be used on all OBD II

equipped systems. The newly designed diagnos-

tic connector for OBDII, officially known as theData

Link Connector (DLC), contains 16 terminals.

Data Link Connector (DLC)

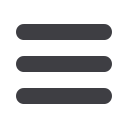

DLC Pin Assignments

PIN Description

1 Discretionary

2 J1850 Bus+

3 Discretionary

4 Chassis Ground

5 Signal Ground

6 CAN High (ISO 15765-4)

7 ISO 14230-4 & 9141-2 ‘K’ Line

8 Discretionary

9 Discretionary

10 Bus negative line of SAE J1850

11 Discretionary

12 Discretionary

13 Discretionary

14 CAN Low line of ISO 15765-4 (J-2284)

15 ISO 14230-4 & 9141-2 ‘L’ Line

16 Vehicle Battery Power

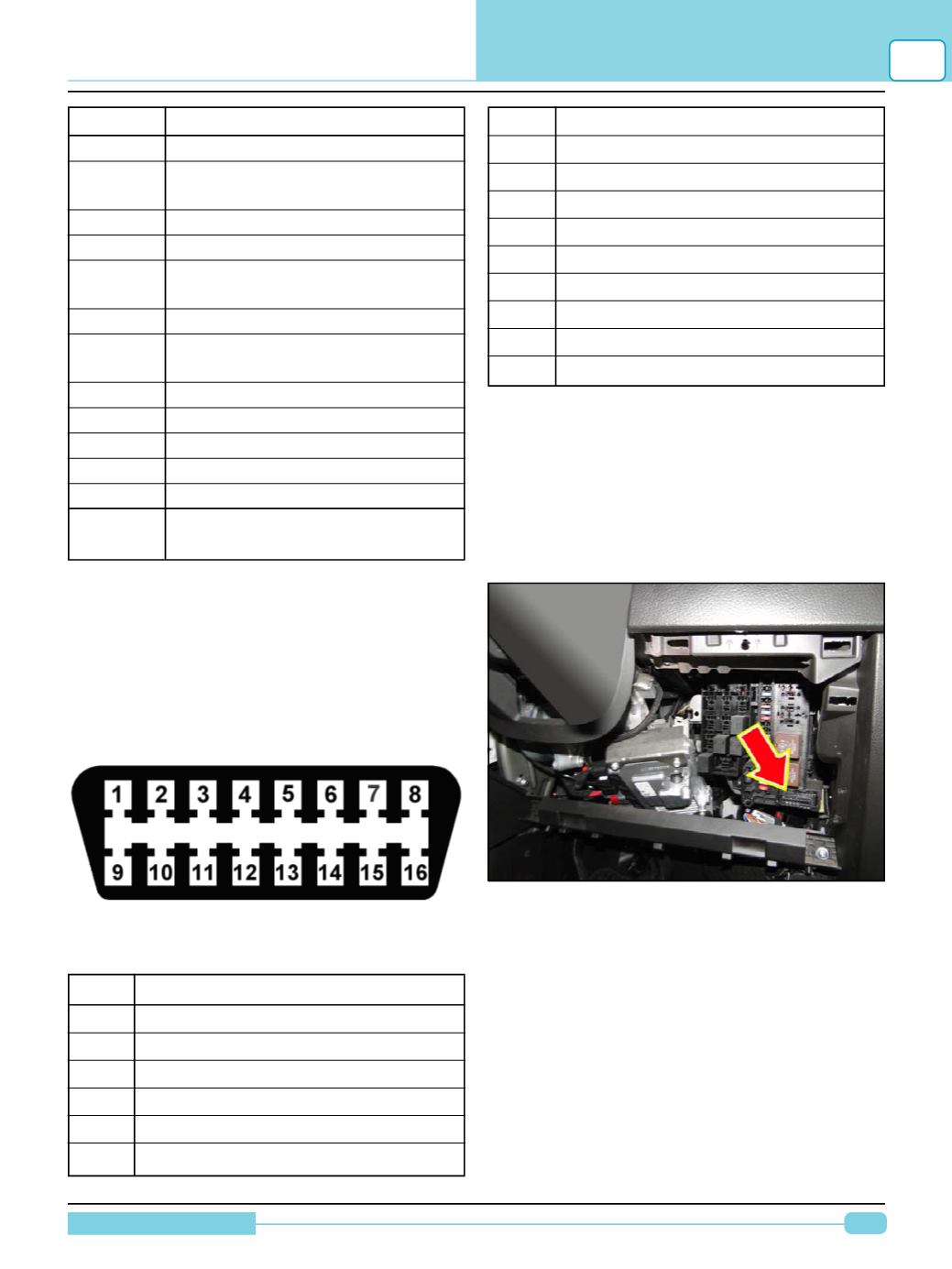

DLC Location

The diagnostic connector is required to be located

between the driver’s end of the instrument panel

and approximately one-foot beyond the vehicle

centerline, on or below the instrument panel. On

most vehicles, the connector is located beneath

the instrument panel, near the steering column.

In

TATAMOTORS

passenger segment vehicles,

DLC location is different from model to model.